Removing G20 trade barriers could boost decarbonisation

G20 countries should remove trade barriers, exchange best practices and establish common standards for green steel to boost the sector’s decarbonisation plans, a new report concludes.

The International Renewable Energy Agency’s (IRENA) Towards a Circular Steel Economy whitepaper highlights the role of recycling, reduced steel consumption and renewable energy in cutting emissions from a sector that accounts for around seven percent of global CO2.

IRENA’s director-general, Francesco La Camera, called for G20 members to lead the way in a global effort to cut emissions from steel production and drive a more efficient circular economy.

“G20 members account for about four-fifths of the world’s production and consumption of steel, and collaboration among members can accelerate the adoption of circularity,” he said.

“By working together, G20 members can lead the way in implementing circularity by fostering the exchange of best practices, removing trade barriers, and establishing common standards for sustainable steel production.”

This month (August) the Global Steel Climate Council (GSCC) launched its new global standard for measuring and reporting steel carbon emissions and setting reduction targets. It is one of several industry groups promoting a global steel standard to help reduce steel carbon emissions.

IRENA’s call for a collaborative global approach to tackling CO2 emissions from steel and iron production comes just weeks after governments and industry bodies in several developing nations criticised the EU’s incoming CBAM regulations as “protectionist” and “coercive”.

Brazilian, South African and Turkish responses to the European Commission’s CBAM implementation consultation suggested the measure would undermine the efforts of less developed nations to decarbonise.

IRENA’s report was prepared in collaboration with the Ministry of Environment, Forest and Climate Change of India (MOEF&CC) as a contribution to India’s G20 Presidency.

Circular economy

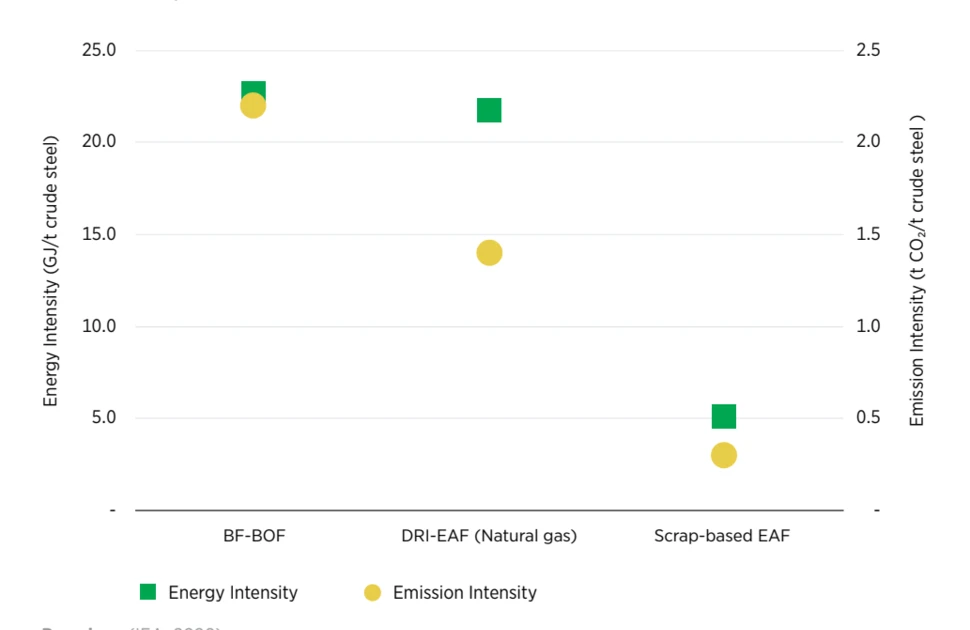

Among the findings of its research into the circular steel economy IRENA said the proportion of steel produced from recycling scrap could grow from around 30 per cent today to around 50 per cent by 2050.

It concluded that increasing the share of steel produced from recycled scrap would only be possible if the growth in global steel consumption was mitigated by “material efficiency measures”, however.

IRENA cited the International Energy Agency’s Iron and Steel Technology Roadmap, which estimated that such measures – including greater use of high-strength steels and alternative materials in construction and automotive – could decrease projected global steel demand by around a fifth by 2050.

Global steel scrap availability is estimated to increase from 770-870 Mt/year currently to 1,250-1,550 Mt/year by 2050, it said.

However, the IRENA whitepaper showed that the exponential growth of steel production in developing nations including China and India had resulted in the share of steel produced through scrap recycling decreasing over the past two decades.

Renewables restructure

Similar sweeping changes will be needed to meet the steel sector’s growing demand for renewable electricity.

Hydrogen-based direct reduced iron that can replace fossil fuels with green hydrogen as a reducing agent was “reaching commercial maturity”, IRENA claimed.

It cited research that indicated the relocation of energy-intensive ironmaking to regions with access to abundant renewable energy sources could reduce global sector emissions by almost a third.

In those circumstances, an estimated carbon price of USD 67/t would make hydrogen-based DRI competitive with a blast furnace using fossil fuels, it claimed.

Significant challenges remain around the exponential growth in renewable energy required to produce the green hydrogen needed to transition to sustainable steel production.

“As a rule of thumb, 1 Mt/year of hydrogen production capacity requires about 10 gigawatts (GW) of electrolyser capacity and at least 20 GW of renewable power to supply electricity”, the report said.

“To put this in perspective, transitioning all iron-producing plants in the European Union to H2-DRI would require up to 5.3-5.5 Mt/year of renewable hydrogen and up to 370 terawatt hours per year of additional renewable electricity generation, which is four times the electricity that the sector consumes currently.”

In one of several recommendations to the G20, IRENA concluded: “G20 members can accelerate a transition towards renewables-based steel by co-operating in several areas, including dialogue towards internationally agreed definitions, standards and certifications for low-carbon steel; initial demand creation through multilateral public procurement commitments; knowledge exchange on technology research and development; professional skills needed for the transition; and technical and financial assistance to developing countries, among others.”

Source:

European Steel Review

The MEPS European Steel Review is an informative, concise and easy-to-use monthly publication, offering unique professional insight into European carbon steel prices.

Go to productRequest a free publication